Carbon Hardtop

When we ordered Puffin from the Outremer factory, we knew we wanted sun protection over the helm station but we couldn’t figure out a good way of doing it during construction, so instead we decided to order the boat with the standard mini roof over the center of the cockpit and removable Sunbrella fabric panels that provide shade over the sides of the cockpit when not sailing. We would then design a replacement cockpit roof after we had used the boat for a while.

I think this turned out to be a good approach because we could take our time to determine how we use the boat and to develop a roof design that met all of our needs, and still felt like it fit well with the overall design of the boat.

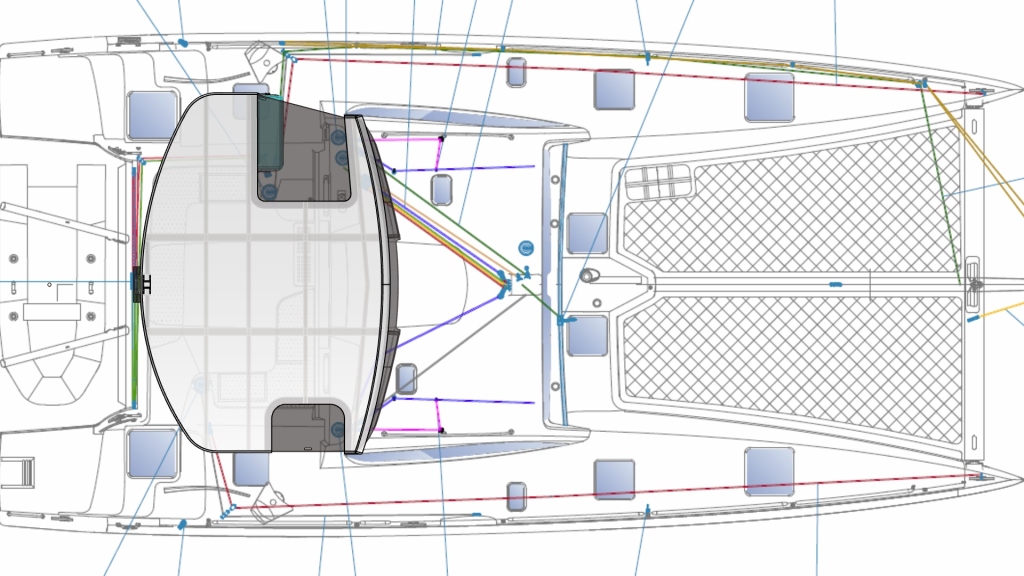

The new hardtop is now complete and installed. We are not quite finished with this project, but I think we are far enough along to share some info and photos of the design and how it works on the boat.

We hired an architect and boat builder team located on the Queensland Gold Coast to work with us on the hardtop design. Our design brief to them was as follows:

- Our primary objective is sun protection. The sun in Australia is intense! Having spent 3 summers sailing in the Med, I would say 30 minutes of direct sun in Australia, is equal to about 3 hours of direct sun exposure in the Med. Sailing vessels in our climate must have sun protection to be safe and enjoyable to use! The entire cockpit area needs to be shaded, and we need to be able to sit at the helm completely protected from the sun

- The hardtop needs to have access openings that allow us to stand at the helm and operate the winches and sail controls without any interference

- The top needs to be high enough that our 6’4″ son can enter and leave the cockpit from every direction without having to duck to avoid hitting his head

- The hardtop needs to fit under the boom with no modifications to the boom height or mainsail shape

- We need to be able to attach clear forward windshield panels to protect from rain and spray. These panels need to be easily removed to allow a breeze into the cockpit when required

- The roof must be able to have removable side and rear shade mesh panels attached around the complete perimeter, so we have full shade from all sun angles for the entire cockpit at anchor

- The hardtop needs to be strong and light. A person needs to be able to walk on all areas, and every option to reduce weight needs to be incorporated into the design and construction.

We iterated over a few versions of the concept and built full size cardboard models to test the dimensions and shape of the design. After about 3 iterations we came up with a design we were happy with.

Once the design was complete, we started construction. The hardtop was built for us by Multi-Marine Australia, a boat building company that specializes in catamarans located on the Gold Coast.

In order to keep weight to a minimum the hardtop was constructed using Duflex foam core, carbon fiber panels from ATL Composites. All layup and reinforcing was done in carbon fiber. We tested rigidity and strength at each step to ensure we did not under-build or add unnecessary weight to the finished roof.

In order to keep weight down we used a single skin roof with exposed structural beams underneath. This required more surface preparation for painting but reduces weight compared with a double skin design that hides the structure.

Here are some photos of the boat back in the water with the new hardtop fitted.

Next Steps

Now that the hardtop is installed, we are moving on to the finishing details. The new helm seat is being fitted behind the steering wheel and the windshshield clear panels and wrap around shade screens are being made. I will post more photos when everything is finished.

Awesome and intense job! We got a Carbon Bimini on our 51 but it doesn’t offer sun protection on the helmet. And we really miss this heavily. Have been thinking a lot about how to get that installed without interfering with the boom and the running rigging.

LikeLike

Love this Setup!! we are looking to do the same! can you give us some help as to how to get it done like you. thanks!

Andres Delgado

LikeLike

Hi Andres,

The best approach is to find a local boatbuilder and show them the photos and drawings of our boat. They should be able to give you an estimate to build and install the roof.

LikeLike

Hi Doug, I love your new hard top. Any idea how much weight it added total? Also, how many watts of solar did you manage to fit on the new hardtop?

LikeLike

Hi John, net add in weight is ~95kg. We installed 6 x Solbian SP130 panels so 780 Watts. With the 600 Watts on the davits this gives us 1,380 Watts total.

LikeLike

Hi Doug

Just a note to say thank you for all your posts. They really are incredibly informative and helpful.

Enjoy your sailing!

Best

LikeLike

Hi Doug

Many thanks for your post which are very helpful to chose the right 4x configuration ( I will have mine delivered in 2024 !)

Just one question, what wrong with the optional hardtop proposed by outremer ?

Have fun

LikeLike

Hi Serge, thanks for the feedback. Outremer offers the same hardtop option on the 4X as the 45. The problem with the factory design is that it’s too low and provides no sun protection at the helm. The low height makes the cockpit area feel closed in and small. Our hardtop is much higher and actually has the effect of making the cockpit feel bigger and more open. The additional height allowed us to add a helm seat and get full weather protection. Now that we have been sailing with the new hartop I’m very happy with it. It has completely transformed the boat for us.

LikeLiked by 1 person

Hi thanks for posting thiss

LikeLike