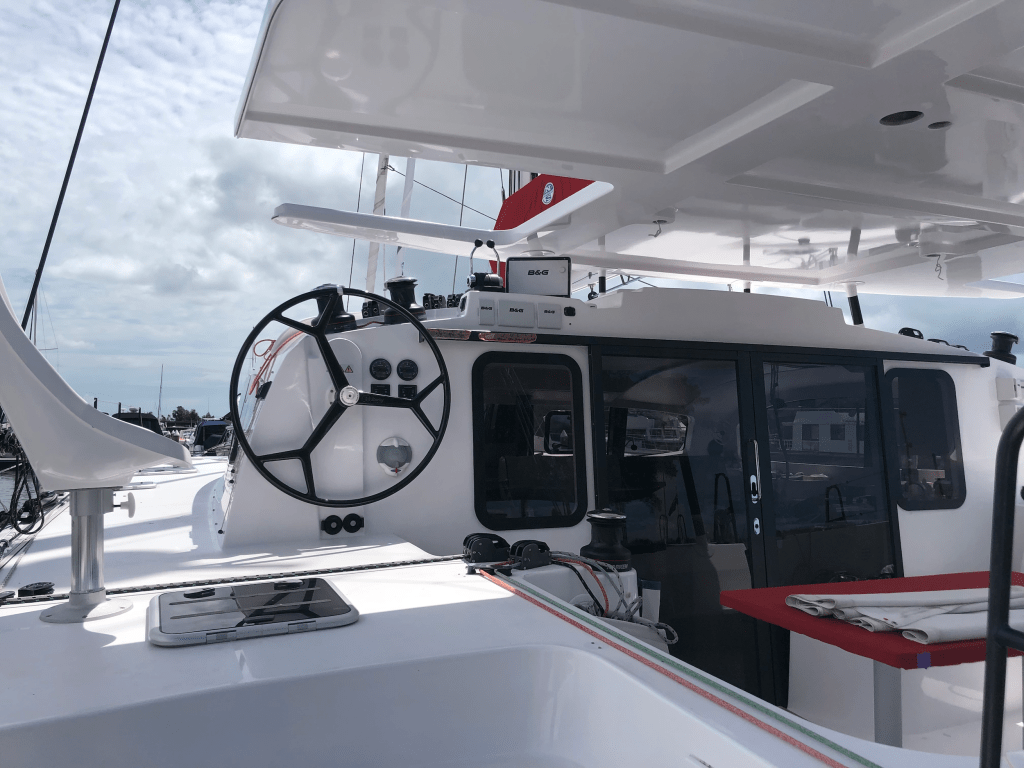

When we ordered Puffin from the Outremer factory, we knew we wanted sun protection over the helm station but we couldn’t figure out a good way of doing it during construction, so instead we decided to order the boat with the standard mini roof over the center of the cockpit and removable Sunbrella fabric panels that provide shade over the sides of the cockpit when not sailing. We would then design a replacement cockpit roof after we had used the boat for a while.

I think this turned out to be a good approach because we could take our time to determine how we use the boat and to develop a roof design that met all of our needs, and still felt like it fit well with the overall design of the boat.

The new hardtop is now complete and installed. We are not quite finished with this project, but I think we are far enough along to share some info and photos of the design and how it works on the boat.

We hired an architect and boat builder team located on the Queensland Gold Coast to work with us on the hardtop design. Our design brief to them was as follows:

- Our primary objective is sun protection. The sun in Australia is intense! Having spent 3 summers sailing in the Med, I would say 30 minutes of direct sun in Australia, is equal to about 3 hours of direct sun exposure in the Med. Sailing vessels in our climate must have sun protection to be safe and enjoyable to use! The entire cockpit area needs to be shaded, and we need to be able to sit at the helm completely protected from the sun

- The hardtop needs to have access openings that allow us to stand at the helm and operate the winches and sail controls without any interference

- The top needs to be high enough that our 6’4″ son can enter and leave the cockpit from every direction without having to duck to avoid hitting his head

- The hardtop needs to fit under the boom with no modifications to the boom height or mainsail shape

- We need to be able to attach clear forward windshield panels to protect from rain and spray. These panels need to be easily removed to allow a breeze into the cockpit when required

- The roof must be able to have removable side and rear shade mesh panels attached around the complete perimeter, so we have full shade from all sun angles for the entire cockpit at anchor

- The hardtop needs to be strong and light. A person needs to be able to walk on all areas, and every option to reduce weight needs to be incorporated into the design and construction.

We iterated over a few versions of the concept and built full size cardboard models to test the dimensions and shape of the design. After about 3 iterations we came up with a design we were happy with.

Once the design was complete, we started construction. The hardtop was built for us by Multi-Marine Australia, a boat building company that specializes in catamarans located on the Gold Coast.

In order to keep weight to a minimum the hardtop was constructed using Duflex foam core, carbon fiber panels from ATL Composites. All layup and reinforcing was done in carbon fiber. We tested rigidity and strength at each step to ensure we did not under-build or add unnecessary weight to the finished roof.

In order to keep weight down we used a single skin roof with exposed structural beams underneath. This required more surface preparation for painting but reduces weight compared with a double skin design that hides the structure.

Here are some photos of the boat back in the water with the new hardtop fitted.

Next Steps

Now that the hardtop is installed, we are moving on to the finishing details. The new helm seat is being fitted behind the steering wheel and the windshshield clear panels and wrap around shade screens are being made. I will post more photos when everything is finished.

I explained in an earlier post that we were purchasing a carbon fiber, rigid (non-inflatable) tender for Puffin. Our tender is made by Offshore Cruising Tenders in New Zealand, and it’s an exceptionally high quality and beautiful piece of craftsmanship. Our tender is the OC330 model and the hull weight in carbon is an amazingly low 39kg. Adding beach wheels and accessories pushes this up to around 50kg, which is still very light.

I initially thought we would go with a Torqeedo Travel electric outboard, but there was almost no information about how the Torqeedo would perform on a tender, and dropping down to 3hp equivalent power seemed just too restrictive, so I changed my mind and purchased a 6hp Yamaha four stroke outboard. This is still a very small outboard, considering our tender on Wildling, a 3.8m Highfield had a 20hp Honda engine. The 6 hp on our OC Tender has worked pretty well though, and with Robin and I onboard we can get on a plane, but it takes nearly full throttle to do it.

The problems with this setup are that the motor weighs 27kg plus another 15kg for the 5 gallon fuel tank, so it’s heavy. It’s also pretty large, and vibrates a lot and is very noisy when it’s working hard. The carbon tender doesn’t flex when bouncing into waves, so the ride can get uncomfortable when going fast. We find ourselves motoring below planing speed most of the time, which is comfortable and gets us around quite quickly.

This made me reconsider the Torqeedo electric outboard option. Since I’m mostly at half throttle on the 6hp Yamaha, maybe the 3hp Torqeedo would do the job? Another search yielded that there’s still almost no information available online about real-world application of the Torqeedo 1103C on a tender, so I decided to be the guinea pig and try it out.

The Torqeedo is very light. Only 17kg for the motor & drive unit including the lithium battery. In fact it’s so light that it’s no trouble at all to take off the tender and store inside the boat in its carry bag when not in use.

Our initial test runs have been quite good. The Torqeedo is able to push us along at 6-8 knots. There’s no way it will get us on a plane though, so we have to adjust our expectations of how we use our tender.

Pros and Cons of the OC Tender and Torqeedo

I would say this solution is really not for everyone. There are some compromises required when going for the lightest possible tender & motor setup. Based on our experience to date here are the points for and against this setup:

Pros:

- Very light, so no loss of performance of our Outremer 4X under sail

- Motor is easy to lift and lower and to fit and remove from the tender

- Very easy to lift the tender up and down off the davits

- No need to deal with fuel tanks, manual pull starting, maintenance and reliability issues of an outboard motor

- No noise and no smell, the motor is pretty much silent

- Motor can be easily taken off and stored in the main boat so more secure

- Battery can be recharged using a portable solar panel, providing renewable energy powered transport

- The OCTender is much drier than a RIB, this means traveling at less than planing speed is not uncomfortable. Often on A RIB you have to get on a plane to avoid getting soaked by the chop.

- Moving the tender around on the shore is very easy. Even for older folks the light weight and beach wheels makes this no problem. A huge benefit when dealing with large tides.

- For those that like stress-free cruising, taking it easy on the tender is more fun!

Cons:

- This is a low speed means of transport. People that like to zoom around in their tenders will probably find it too slow

- Motoring into steep waves and wind is slow. In these conditions, the lack of power from the Torqeedo could cause safely concerns

- Limited to short trips. The range is about 8km on a charge under normal use. This makes it better suited to short trips between the anchorage and shore, and not good for long exploration trips, although reducing speed and carrying an extra battery would boost range to around 20km.

- Have to wait for the battery to recharge after use. This can be solved with an extra battery so there is always a fully charged battery available.

- The OCTender is less stable and more weight sensitive than a RIB. This is not an issue when underway, but getting in and out requires more care than a RIB. The lack of soft tubes to sit on makes the ride less comfortable, but this can be improved by carrying some foam pads to use when climbing aboard and sitting on the sides.

Our conclusion

We’re getting older and our backs and knees aren’t what they used to be, so we’re not really interested in going fast in small tenders. This lightweight, electric setup is really good for us. We love the ease of use and portability of both the tender and the motor. It’s also very satisfying to know the tender is not a weight penalty when we are under sail. The only change we are making is that we are ordering an extra battery to give us some safety margin.

After a few weeks in Coffs Harbour, a southerly front arrived, so we took advantage of it to make the final passage up to Brisbane, and Puffin entered her home port for the first time.

It was a pretty fast passage, with 20-25 knot winds directly behind us. I unfurled the genoa and used the outboard lead block to give us a good downwind sail shape and Puffin was doing an easy 7-9 knots all the way up. We had a few areas where the East Australia Current was doing 3.5 knots against us, causing some lumpy seas and slow progress, but for the most part it was an easy passage.

Our tracker plot of the passage up to Brisbane. The Eastern line is the track from Happy Delta going down to Newcastle.

We crossed the bar at Southport and followed the Gold Coast Seaway on the western side of the Stradbroke Islands up to Moreton bay. It’s always a bit tricky navigating the seaway as the water is very shallow in places. Less than 1 foot of clearance in some areas, but we made it through all the way without touching.

Volvo Warranty

We didn’t have any problems with Puffin on the passage from Coffs to Brisbane, but there were a few things we needed to take care of when we arrived in Coffs Harbour.

I noticed the gearbox oil in the starboard engine was a bit milky. Outremer gave me the number to call Volvo Penta Support directly. This is a number in Belgium, so I was a bit concerned how well they would take care of us in Australia. I called the Belgium support line and explained the issue. Within 30 minutes, I had a call back from the head of Australian Volvo in New South Wales, who discussed the issue and referred me to Thwaite’s Marine in Coffs Harbour. Ben at Thwaites called me less than an hour later and we set a time to meet at the boat.

Ben checked the engine and dived the prop to look for any lines wrapped around the shaft. There were no lines, but he found evidence there had been a line that was no longer there, but had pressed on the shaft seal causing a small leak. The seal was undamaged, so he changed the oil and asked me to keep an eye on it. I checked again when we arrived in Brisbane, and the oil is clear, so all good.

It’s the first time I have used Volvo’s Warranty support, and I am very happy with their response and how professional and helpful everyone at Volvo was. This all happened during the Australian Christmas holidays, so the Volvo people in Australia were not at work, but they still took care of me right away!

Australian Sun

The only thing I don’t like about Puffin is that we don’t have any shade protection at the helm. This is not a big issue in the Mediterranean, but in Australia the sun is fierce! It’s interesting to note the different reactions from people that see the boat. In Europe the first thing they usually ask me is how fast she sails. In Australia the first thing, is “Why is there no shade at the helm?” I knew this when I bought the boat, but there are so many great features I liked, that I decided to try and fix the shade issue after I got the boat back to Australia. I will be working with a boat builder here in Brisbane to try and come up with a design that adds shade without interfering with sailing, and will report back when I have a plan.

Puffin arrived in Australia last week! Robin, Gavin and I went down to Newcastle to take delivery of her as she came off the ship. The lift down from the deck of Happy Delta went smoothly and her engines started right up when the lifting slings were removed from underneath.

We motored her over to the nearby marina and waited for the quarantine officers to inspect for bugs!

We had our YB3i satellite tracker running on PUFFIN throughout the voyage, so we received position updates every 4 hours.

The quarantine inspection went fine, no Brown Marmorated Stink Bugs on board and the Australian agents were friendly and professional. Once we were given a clean bill of health by quarantine (and after a celebratory beer!) we could get to work with re-rigging and cleaning. The boat was undamaged from the voyage but very dirty. The protective wax that Kirk and I put on in Genoa worked very well and she looked like new again after the cleaning was done.

We went out for a test sail on the weekend and everything worked fine. I made a mistake with the routing of the leech reef lines, so I have to fix that as soon as I can hoist the mainsail when there is no wind. It’s not a big issue, but it means we can’t fully reef until I fix it.

Puffin will be in Newcastle for just a bit longer until Lindsay finishes her end of school year exams, and then we will be sailing her up the coast to Brisbane.

After Robin and I did the handover and training on Puffin in August, we left the boat for a few weeks so Outremer could take care of our list of repairs and adjustments. I returned in September with Robin’s brother, Kirk to take Puffin to Genoa and get her ready to load on the Sevenstar cargo ship for the transport to Newcastle, Australia.

All of the items on our list except one were completed. I met Stephane from Outremer on the boat the morning of our departure and went through everything. The only thing they didn’t have time to finish was the privacy curtain in the owner’s hull. The fabric is a special order so it didn’t arrive in time. No big deal though, Stephane will send it to us in Brisbane and I will work with the Australian Outremer dealer, Multihull Central to get it installed.

Stink bugs?

With Puffin all ready to go, Kirk and I left La Grande Motte for our voyage over to Genoa, Italy. Our original plan was to load onto the Sevenstar ship in Palma Majorca, but it turns out that Australian Quarantine requires that all cargo (including yachts) departing European ports for Australia must be treated for Brown Marmorated Stink Bug. This little bug apparently causes a lot of crop damage and is not at all welcome in Australia. There are no Australian Quarantine certified Stink Bug fumigators in Palma, but there are in Genoa, so off to Genoa we go.

Our trip over to Genoa took about 3 days, including a stop to anchor overnight near Cannes to wait out some strong headwinds. We had to motor a bit more than we would have liked due to no wind in the beginning and strong headwinds at the end, but we did get some great sailing in as well.

What I learned about Puffin on this voyage

This was my first multi-day voyage on Puffin so there was a lot to discover. We used all of our sails except the gennaker, and we sailed with reefed main and staysail for part of the way and with full main and genoa for other sections. It gave me a chance to get to know Puffin a bit more. Here’s what I learned:

- Puffin’s sails and sail handling systems work really well – Managing Puffin’s sails is very easy and everything that I wanted to be able to do single-handed worked well. Performance was excellent in light winds and the boat was easy and balanced when reefed down.

- Puffin’s motion continues to exceed my expectations – We sailed in some rough conditions with 30 knot winds and waves, and the motion is definitely more comfortable than our previous boats. It’s hard to explain, but basically the lighter weight reduces the motion because there isn’t the lurching sensation that you get with heavier boats as they tend to dive up and down in the waves. Craig Schionning talks about this on his website as one of the benefits of light catamarans, but until I experienced it for myself, I didn’t really understand what difference it would make. I’m not saying that Puffin will be more comfortable than a longer, heavier boat in all conditions, but based on my experience so far it is definitely better.

- Motoring is easy and efficient – We did some overnight motoring runs on this trip and I was able to experiment with different engine configurations. I did a full speed test on flat water with no wind and no current. With both engines at full throttle we did 3,200 RPM on each engine and boat speed was 9.6 knots. I found that I could get 5 knots speed on a single engine at 2000-2200 rpm. At this configuration we burn 2 liters of diesel per hour which gives us around 160 hours motoring range on a full tank.

- The reef hook needs the mainsail to be unloaded to operate correctly – I found that when taking the first reef in the main using the Facnor reef hook, we needed to come up quite far into the wind to take the pressure off the sail. If the sail has too much pressure, the hook will not engage on the leech shackle. I found the best approach was to run an engine to push us a bit higher upwind to engage and disengage the hook.

Full main and genoa on a calm sea. We were able to sail in winds 4 knots and above at very close to true wind speed

Problems

We had three problems on this trip. There was a water leak from around the engine control levers at the helm station which leaked water into the cupboard above the salon fridge and down into the closet in the port hull. There was a loud creak coming from the shelves behind the stove in the salon, and we had an intermittent issue on the last night of the trip where the autopilot occasionally lost the boat speed data and sounded an alarm.

I called Stephane from our anchorage in Cannes about the water leak as this was a serious issue that could cause a lot of damage if it leaked during the trip back to Australia. Stephane agreed and sent Jerome, one of his technicians to meet us in Genoa. Jerome fixed the water leak and the creaking shelves. I’ll need to do some more testing on the intermittent B&G issue when we get back to Australia.

Preparing Puffin for transport

Sevenstar give detailed instructions about how to prepare your boat for deck cargo on their ships. In addition to this, I talked with some yacht captains that had experience shipping boats with various transport companies. Everyone agreed that the boats will get very dirty and any canvas on deck should be stowed and the sails removed and stowed also.

I also decided to remove all of the running rigging and replace the lines with messengers so we can easily reinstall everything in Newcastle. We applied a surface protection wax on the entire deck and the mast, and we wrapped the boom and as many of the fittings as possible in UV resistant stretch film and tape.

I called North Sails after we arrived in Genoa, and they came to the boat the next day and took down the genoa and mainsail and stowed them in their sail-bags for us. It was a huge help to have this done by professionals and we were really impressed by the great support provided by North!

We used Aurora Marine products to protect the gelcoat and non-skid deck surfaces on the boat. We used Sure-Step on the non-skid and VS721 on the smooth gelcoat and mast.

Bug furnace

The final step in the prep process was the stink bug fumigation treatment. This was done via ducted industrial heaters that pump heated air into the interior of the boat to kill any bugs. This was some serious equipment and was pretty scary as we didn’t know what damage would be done by the heat. Unfortunately there’s no way to enter Australia without fumigation, so we had no choice. Once the treatment was done, we found that the plastic frames around our salon fans had warped in the heat, so the fans will have to be replaced.

The plastic frames around our salon roof hatch blinds were also damaged by the heat treatment, but I didn’t see any other damage on the boat. We will have to purchase replacements from Outremer and fit them in Australia.

Happy Delta

The Sevenstar ship that is transporting Puffin is named Happy Delta. We were given a loading time by the Sevenstar loaders and at the designated time we drove Puffin over to the port of Genoa to load onboard.

The Sevenstar loading team is very professional and they had no trouble lifting Puffin onboard and securing her on deck.

First we were asked ot come alongside the ship. The loading crew climbed down the boarding ladder and positioned the lifting slings in place. A diver was under the boat to verify the slings were positioned correctly.

They begin the lifting and as soon as the boat deck reaches the deck of the ship we climbed onto the main ship and were given hard hats and a place to watch from a safe distance.

They swing the boat into position onto the ship deck and then prepare the wooden block supports. I was invited to supervise this to make sure the blocks were positioned correctly.

Once the boat is lowered onto the blocks, they tie it down with heavy duty ratchet straps. Next they position lateral support blocks on the inside hull surfaces and weld them to the deck. This ensures there’s no possibility of the boat moving sideways on the blocks during the passage.

Now we have a long wait until Puffin arrives in Australia. We won’t be given an ETA by Sevenstar until Happy Delta is underway. The voyage plan is to stop in Turkey to pick up some motor yachts and then travel to Australia via the Suez Canal.

Here are some tips based on my experiences purchasing two Outremer catamarans. I took the lessons learned from buying our 5X and applied them to the construction of our 4X. This worked well for us, Puffin was delivered on schedule at the estimated price. There were a few problems that came up, but nothing serious. I have listed these at the end of the post in Lessons Learned.

1. Write a master specification document

There are too many details to keep track of if they aren’t written down in a master specification document. Outremer will compile a list of the options you have ordered, along with the price for each item and will send this to you for approval before proceeding with the build. The Outremer list doesn’t contain all the details of how each item will be built, so you will need to provide additional details. For some things it’s simple and a detailed description isn’t needed, the color of the boom for example. For other items, a detailed description with drawings or photos is needed to ensure the factory fully understands what you are asking for. Locations of remote controls for electric winches for example.

2. Find out what features are standard

Your order will start with the standard boat, and then your optional features will be listed. It’s important to know what is and isn’t included in the standard boat, otherwise you may end up missing a feature that you thought was standard, but Outremer considers an option. Looking at photos of other boats or even the sales brochure may not help, because pretty much every boat has some non-standard items. In cases where I wasn’t sure, I listed the item in my master spec to be sure it wasn’t left out, but it’s impractical to do this with every standard feature. Best to have a thorough discussion with Outremer when you begin the specification process.

3. Visit the factory periodically to make sure your boat is being built to your spec.

Outremer has good quality control, but boats are incredibly complex, so it’s inevitable that some details will get missed or instructions misinterpreted. I wasn’t able to travel to France during the construction of Puffin, so I hired a local consultant that I trust, to do regular inspections for me. I worked with Sandie Moreno from Services Plaisance. Sandie is a certified delivery skipper and has thousands of miles experience sailing and maintaining multihulls, and has acted as owners representative on the construction of multiple large multihulls. She helped me with a delivery passage on Wildling when I was short-handed and I found her to be excellent, both technically and as a sailor. Sandie visited the factory multiple times to check Puffin’s construction against the spec. and she sent me photos of each item. She caught some things with our North sails that were not correct and a few minor construction details that Outremer corrected before delivery, which helped keep the project on schedule and made sure nothing was missed.

If you would like to work with Sandie, you can contact her at: servicesplaisance@gmail.com

4. Schedule time to fully exercise your boat after handover

Plan to spend some time living on the boat after the handover week is complete. Be sure and go over every system and check its operation. Check for water leaks and loose fittings. Wash your boat and wipe the entire boat dry with a cloth. This ensures you check every square inch of the boat to find any scratches or surface defects that need to be fixed. Outremer will schedule a first warranty service for your boat soon after your sea trials and shakedown cruise. This is the time to get anything that isn’t quite right taken care of before you leave La Grande Motte.

5. Don’t forget it’s a boat

If you’re buying your first new boat, it may come as a surprise to find that your new boat will have some issues, and that things will break when you start using it. We’ve become so accustomed to new cars having no defects, and even no need for a service during the first year of ownership, but boats are different. They are hand crafted and hand assembled. There are thousands of individual components that have to fit together perfectly, and they operate in one of the most challenging environments on the planet. Your boat will have some items to fix, and it will require constant maintenance and repair even when it’s new. Outremer knows this and has an entire team dedicated to supporting new owners. This is why the service and support provided by your manufacturer should be one of the most important criteria when buying a new catamaran.

Lessons learned

I followed the approach described above when building Puffin and everything went well with the construction of the boat. Sandie found a few things that Outremer corrected before launch and Puffin was delivered on schedule and on budget.

Only one of my specified options was not installed before delivery, the privacy curtain at the entry to the starboard cabin. This was due to a misunderstanding over whether it was an optional or standard feature (see Tip 2 above). Sandie caught this, but it wasn’t addressed prior to delivery. Not a big deal and Outremer will add it during the first warranty service.

We did have a few problems with the North sails. Sandie caught all of these issues before delivery, but after they had been installed on the boat, and it was too late in the process to correct everything, so North still has some work to do.

Here are the issues we had with our North sails:

- The 3Di Mainsail was delivered and installed on the boat with sail numbers on the sail. I had specifically ordered the mainsail with no numbers, but it was delivered with a sail number of ZZZ888. These numbers were each about 500 mm high, but neither North nor Outremer caught this. Sandie found it during an inspection and North removed the numbers before delivery with no damage to the sail

- The North spinnaker was the wrong size and the wrong fabric. North had no issues replacing the spinnaker, but it was too late to get a replacement made before delivery so we are sailing without our spinnaker until North can manufacture a new one.

- The Staysail bag is too small and does not fully cover the sail when stored on deck. Both Outremer and Sandie caught this, but North did not fix it prior to delivery.

The North sails on Puffin are beautifully made, so there are no issues with the sails themselves, but the quality control process between North and Outremer needs some attention. If you order North sails with your boat (and I recommend that you do) you should add an inspection step to verify the sails have been constructed according to your specifications before they are fitted on the boat.

I didn’t have a video camera and microphone with me during our first week of sailing Puffin, so I recorded this video tour with my iPhone. I clearly don’t know much about iPhone videos as the orientation is not correct, but Robin convinced me I should post it anyway. Please view at your own risk 🙂

Robin and I arrived in La Grande Motte last week and were given the keys to Puffin! She is all finished and we couldn’t be happier with her! The Outremer team has built us a magnificent boat. The level of finish and craftsmanship that has gone into Puffin is truly impressive, and Robin and I owe a huge THANK YOU to everyone involved!

Delivery of a new Outremer catamaran includes an action packed week of briefings, instruction, maneuvers, testing and practice. It’s fun and tiring, and at the end you feel like you really know how to operate and manage your new boat and you’re ready to set sail! Here’s what happened during our Puffin delivery week…

Day 1 – Meet the boat

The week of delivery is fully scheduled and managed by the Outremer delivery team. We arrived on Monday and met with Benjamin and Matthieu at the Outremer offices, and they took us over to see Puffin and gave us a tour of the boat. Monday was also Robin’s birthday, so she received a pretty epic birthday present that’s for sure!

Day 2 – Final signatures & first sail

On Tuesday morning we met Benjamin at the boat and went over all the delivery paperwork. We reviewed every item on the specification list and made sure everything was installed correctly on the boat. Then we signed the delivery acceptance documents and Benjamin left us to spend some time on Puffin so we could begin to get to know her.

During the afternoon we went on our first sail. We were accompanied by Patrick, who is an experienced ocean sailor, a great teacher and a super nice guy. We had winds of 10-13 knots so we put up the full main and 3Di Genoa. Puffin was easily doing 9-11 knots close hauled upwind in these conditions. I expected her to sail well, and I was not disappointed. I realized that I have never been on such a light catamaran before, it feels quite different. The motion is very easy, you can feel how well she glides over the choppy water. The light weight combined with our awesome North 3Di sails means that every puff of wind translates into forward motion, so the boat feels like it’s not under any stress at all. Robin loved how simple and easy she is to sail. We tacked and gybed a few times and it was no effort. We both felt that all our work to keep the boat light was really worth it!

One surprise for me was how high she points upwind. We could sail fast at 30-35 degrees apparent, and she doesn’t lose speed until we pinch up towards 25 degrees. This is better than any other multihull we have sailed.

On Tuesday Xavier Desmarest, CEO of Outremer came for a visit and we chatted about catamarans – my favorite subject!

During our sail on Tuesday we had problems with the autopilot losing its rudder angle data and disengaging. We had to turn off the autopilot and hand steer, which I didn’t mind because it gave me some time to get the feel of our cable steering system (smooth and direct) and also to try helming with the tillers, which is a pretty unique sensation on a 48 foot boat. Hand steering is fun, but we certainly had to get the autopilot fixed! Patrick called in on the way back to the dock and arranged for Pochon to come and look at the pilot problem.

Day 3 – Electrical systems and downwind sailing

Thomas from Pochon came to the boat on Wednesday morning and found the autopilot was getting interference from the NMEA 2000 barometric pressure sensor. He disconnected the sensor and the autopilot has worked perfectly since. This is aggravating, because I had the same problem when I tried to add a barometric pressure sensor on Wildling. The autopilot went into alarm when I connected it, and I never found a solution. I assumed the B&G autopilot didn’t work with barometers from other manufacturers, so for Puffin I ordered a B&G brand barometer, and guess what? B&G autopilots don’t work with B&G barometers either! The Pochon guys say they see this often when adding a barometer to B&G networks. So no electronic barometer on Puffin until B&G can come up with a fix!

Also on Wednesday morning, we met with Stephane Denner who manages post warranty services for Outremer yachts. We worked with Stephane on Wildling, so we know him really well. He’s a great guy, super knowledgeable, and responds quickly whenever we need help or to answer questions. Outremer yachts include a 2 year warranty so having great people like Stephane to help is an enormous value. Stephane went through all the electrical systems on the boat with me. It was a very thorough tour and involved a lot of tips and tricks for troubleshooting if anything goes wrong.

Wednesday afternoon was more sailing. Winds were a bit lighter so we sailed upwind away from shore for a few miles under main and Genoa, and then returned downwind with our Code-D gennaker. We gybed the gennaker to get a feel for how the sail handles. Once again everything was easy, fast and low stress. Robin and I are pretty much in love with Puffin at this point!

Day 4 – Electronics briefing and reefing tests

Thursday morning was the electronics briefing with Alain from Pochon. This included all of the sailing instruments, autopilot, navigation, radar, communications, video and data systems on the boat. Alain did the installation on Puffin himself, so he knew every detail of how things were installed and configured. He was very detailed and covered the location and setup of every feature on the boat, and like Stephane the day before, he gave me a lot of advice on how to troubleshoot different kinds of problems when underway. Information I was going to use sooner than I thought!

On Thursday afternoon we went sailing again with Patrick, and we also had Thomas from Pochon along. Our plan was to test the B&G electronics while sailing, and then try out the staysail and mainsail reefing. We also wanted to test the Watt & Sea hydro-generator.

We hoisted the staysail and tried out the mainsail 1st reef using the Facnor hook system. The hook works well, it just has to be fully opened before taking the reef, otherwise it doesn’t latch properly. Once Patrick showed me how to operate the hook, we reefed and un-reefed a few times to test it out. It’s very easy, and all done single-handed from the helm station.

The staysail is self-tacking, so we tested it out using the B&G autopilot auto-tacking feature. It’s pretty cool to just press a button on the pilot controller and have the boat tack on its own over to the exact same wind angle on the opposite tack without touching the helm or adjusting the sails!

We fitted the hydro-generator to its bracket on the stern and set it in the water to test its operation, all good!

Thomas spent some time showing me some of the features of the B&G system I wasn’t familiar with. I learned how to quickly set VMG laylines to waypoints, which I haven’t done before. We also tested the radar and checked it’s calibration by setting it to overlay the radar image onto the coastline shown on the chart.

At one point during the afternoon, Thomas inserted a defect in the instrument system without telling me. I was sitting at the helm seat when the B&G plotter went into alarm. I called Thomas over to show him we had lost our GPS position! He said “You just lost your GPS position, what are you going to do?” OK, so I guess this is a test to see if I was paying attention!

First I made sure our autopilot was still helming us. We still had course info from the electronic compass, so no worries for the autopilot. Next I went through my mental, instrument troubleshooting routine. 1st check communications between the GPS and chartplotter, then check the sensor. During the morning briefing, Alain had shown me how to check communications between different components on the system, so I went to the B&G plotter at the nav station and found my way to the GPS data source settings, and voila no GPS source selected! I selected the GPS source and our B&G system alarm disappeared and we had position data again! Nice one Thomas!

Day 5 – Plumbing systems briefing and anchoring

Friday was our final day of delivery week. Stephane came to the boat in the morning and we went through all of the plumbing systems. Fresh water pumps, hot water heater, water maker, filters, toilets, holding tanks, diesel plumbing and sea water pumps. Lots more great information and instructions on how to service everything and avoid common problems. Outremer are using a new variable speed pump that has a microprocessor controlled sensor to shut the pump down and alert if it loses prime or gets blocked. I’ve never used this type of pump, so I learned a lot from this briefing with Stephane.

Friday afternoon was more sailing and the focus of the day was testing our anchor and windlass and measure out our combined chain and nylon rode. We set a course for the anchorage and since we had wind on the nose, I motored the 3 miles over to our anchor location. I hadn’t really used the engines aside from leaving and returning to our dock so it was a good chance to give them a run and make sure they were working well.

When we reached the anchorage I picked an open area away from other boats so I had room to run out our entire 50 meters of chain. We dropped the anchor and laid out all the chain and attached the bridle. The boat stopped immediately, which is the usual with an Ultra anchor, they set fast with no drag, so you have to be careful to not go backwards too quickly as there is a strong jerk on the windlass when they set. All the chain was present and accounted for, so we stopped for a bit to have a swim.

As usual in the Med, while we were anchored, another boat decided to anchor right in front of us, over the top of our chain. There was clear space all around, but for some reason they needed to be right on top of us! Most of the sailors in France are pretty friendly though, so they will usually move if they are blocking your chain. I used our video camera to help with raising the anchor as I could easily see the angle of the chain to the bow so I could position us correctly as we pulled in the chain. The wind shifted a bit so we were able to sneak by the monohull in front of us and get the anchor in without a collision. The sail back was downwind so we unfurled the genoa and gybed back to the port. A nice way to end our delivery week activities!

What’s next?

With delivery week all finished we spent the next few days moving our things aboard the boat and making a list of items to be repaired at our first warranty service at the end of August. It was a pretty short list, and Stephane has promised he will get everything taken care of before we take the boat over to Genoa to load onto the cargo ship in September.

Coming up soon, I will post a video tour of Puffin, and will do another post with more detail about the construction process and share some tips from what we learned along the way.

A big thanks to Matthieu for taking this video of Puffin’s launch!

Puffin is in the water and the Outremer team is finishing off the final details to get her ready for handover. In this post I will describe the electronics, communications systems and sailing instruments we have selected.

Choosing a manufacturer

When it comes to instruments and navigation systems for boats there are a lot of choices from many different manufacturers. I chose B&G equipment for Puffin, here’s why:

1. Focus on sailing

We need instruments that perform well offshore in difficult conditions for extended periods. B&G spends a lot of their R&D effort developing products and features for offshore sailing boats. The Volvo Ocean Race boats all use B&G for this reason. If I wanted instruments for a power boat I would look at Raymarine for a similar reason, but for sailing I prefer B&G.

2. Product volume and market share

I don’t want a small manufacturer with a niche focus on say, just racing. It’s difficult to continuously evolve complex, mission critical software when there is a small user base to exercise all the features and identify problems. More software installed in a wide variety of applications ultimately leads to better software products. B&G has a large customer base in the sailing community both in racing and cruising so I’m comfortable with their ability to deliver reliable software, with minimal upgrade issues when moving to new versions.

3. Familiarity with the equipment

I’ve used B&G for many years and I know it well, which makes it easier for me to operate and troubleshoot when there are any issues.

Puffin’s Instrument Package

Puffin’s nav station. On the left is a 16″ B&G Glass Helm MFD with a separate UI controller on the desktop. At night I divide the MFD screen in two with the chart plotter and AIS overlay on one side and the radar display on the other. The glass helm gives us more display area for divided screen modes.

Outremer works with Pochon, a marine electronics company that does all of the electronics design and install on Outremer yachts. This was also the case when we built Wildling, and I found it worked very well. Pochon does nothing but electronics, and their staff are all highly trained on the latest equipment. I worked directly with Didier at Pochon on our instrument package and he was excellent. He listened to what I wanted and recommended the best solutions based on not just the manufacturer information, but Pochon’s experience with how the equipment has performed on other boats. We worked through alternatives when there were multiple choices available, and he recommended some things I hadn’t thought of.

The schematic above covers all of the equipment for navigation and sailing. I’ll go through them all by location on the boat. Some of the equipment in the diagram is surrounded by a dashed box which indicates optional. This has to do with what’s included in a standard 4X instrument pack, with the optional items being extra equipment that I added to Puffin. Everything in the diagram is installed on the boat.

Navigation Station

The nav station is one of the primary locations used by on-watch crew to monitor the boat and keep a lookout for traffic. At the nav station we have the 16″ MFD. The MFD gives us access to the auto-pilot control, but I added a dedicated auto-pilot controller because I don’t like having to call up the software pilot controller on the MFD when I am using it for something else. We also have an H5000 display so I can always have important information displayed no matter what the MFD is showing. This would typically be depth wind speed and wind angle. There is a VHF radio at the nav station and a remote VHF station at the port helm. Behind the nav station is our AIS transponder. This is a Vesper XB8000 AIS which is connected to the B&G MFD.

Port Helm

The port helm has an autopilot controller, a 9″ MFD which I find important to have at the helm when anchoring or docking, especially at night. We have the H5000 display same as the nav station, and I have a small Triton display which I leave set to a graphical representation of true and apparent wind speed and angle. This gives me constant, easy to read wind information and frees my other instruments for monitoring boat speed, depth and course. There is also a repeater VHF handset at the helm.

Starboard tiller helm

I use the tiller helm seats all the time when sailing, so I have a set of instruments on the starboard salon bulkhead angled towards the helm chair so they can be easily monitored.

Owner’s Cabin

There is a Triton display in the starboard aft cabin so we can keep an eye on wind, boat speed and depth when off watch.

Mast

On the mast we have the wind sensor, antennas for the VHF, WiFi booster, FM radio and Iridium GO satphone and a mast mounted video camera.

We do a lot of sailing around coral reefs in Australia and the Pacific, so having an aerial view helps a lot when navigating between coral heads. It’s also very useful when anchoring.

The radar dome is mounted on the mast spreader. Since we have a fixed mast there is no issue with the software having to correct for the mast angle when displaying radar targets.

Autopilot

We’re using the Precision 9, 9-axis compass. This is all solid state compared with the flux-gate compass that we had on Wildling. I had some issues with the flux-gate losing its bearing when we were slammed by waves from the side when offshore. I replaced it on Wildling with the Precision 9 and it was fine ever since.

The autopilot is B&G with a hydraulic drive. I haven’t used a hydraulic autopilot before, but Pochon have found them to be very reliable, so I went with their recommendation.

Sensors

In the hull we have the boat speed, depth and temperature sensor, and I added a barometric pressure sensor as well.

Communications

We have a Fusion Stereo which allows media playback via Bluetooth. There are two speaker zones in the salon and cockpit, so we can adjust the volume in each location.

We have a WiFi booster and LTE router which gives us internet access vie either shore WiFi or mobile data networks. The router also allows us to leave a webcam connected to watch the boat remotely.

Satellite Tracking

For tracking we chose the YB3i system from YB Tracking. We had this system on Wildling and it was excellent. Their data plans are very affordable and the system is easy to configure via a smartphone App.

I tried to keep Puffin’s electronics as simple as possible, and included the features we found valuable on our previous boats, plus a few extras that I wished I had in the past. I’ll post an update when we have done some sailing and report on how things are working out.

Recent Comments